La introducción del inserto de PCBN con punta WNMG

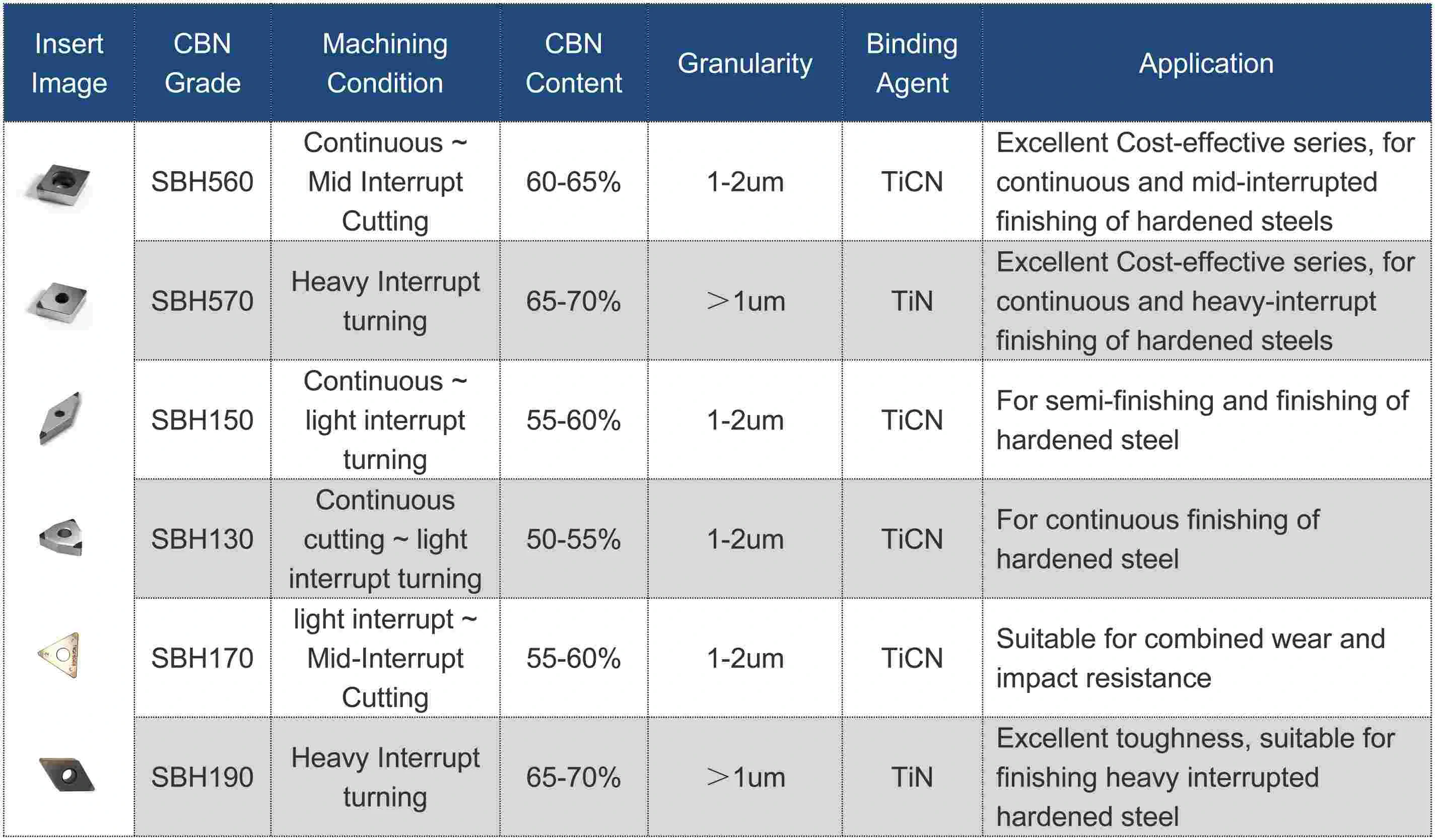

WNMG es un inserto en forma de melocotón de 60 grados, que está hecho de lámina compuesta de PCBN con un excelente rendimiento. Es un inserto de PCBN compuesto con una base de carburo incrustada con una punta de CBN. A menudo se utiliza para el acabado y semiacabado de hierro fundido y acero endurecido. , es un inserto de torneado cilíndrico de extremo muy utilizado, los grados de material comúnmente utilizados son los siguientes:

Las plaquitas de PCBN compuestas con incrustaciones de la serie WNMG son plaquitas de torneado muy utilizadas, que pueden soportar condiciones de mecanizado interrumpidas continuas, intermitentes y pesadas. Existen diferentes tipos de materiales de inserción de cbn para piezas de hierro fundido y acero endurecido, que pueden satisfacer completamente las diferentes necesidades del cliente.

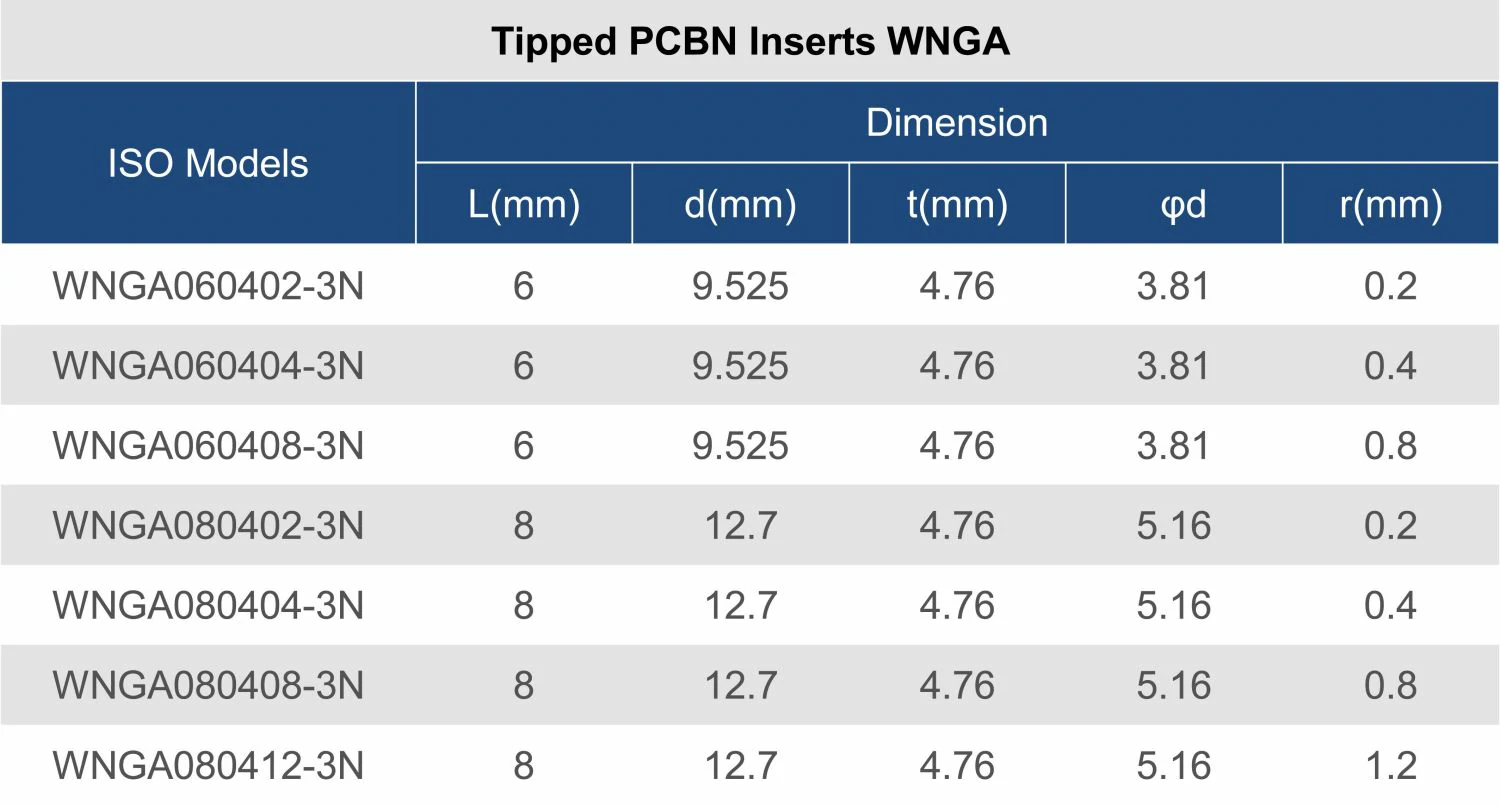

Insertos de PCBN compuestos WNMG Insertos de melocotón de 60 grados de tipo estándar ISO convencional, los modelos de uso común son WNMG0604, WNMG0804 etc. Esta serie de insertos también se puede personalizar mediante soldadura de doble cara según las necesidades del cliente, de modo que se pueden personalizar 6 filos de corte, radio de punta y bordes de corte.

Los insertos de PCBN compuestos de WNMG se utilizan a menudo para piezas de trabajo después de un torneado y enfriamiento duros, como el acabado de caras de extremos de engranajes, círculos exteriores de engranajes y ejes de engranajes, etc. La rugosidad puede alcanzar Ra0.4. Al terminar por lotes piezas de trabajo de hierro fundido gris, como discos de freno, tambores de freno, cuando el bloque del motor está hecho de insertos de PCBN compuestos, el acabado de la superficie es mayor y la eficiencia también mejora en gran medida en comparación con el carburo cementado.

Al mecanizar piezas de acero endurecido, se pueden recubrir las plaquitas de PCBN compuestas de WNMG. Después del recubrimiento, la vida útil de la herramienta aumentará entre un 30% y un 45% en comparación con los insertos sin recubrimiento, y también mejorará el acabado.